PETKUS continuous flow dryers type DWU are designed for drying cereals, maize, oilseeds and free flowing granules such as clay minerals and straw granules. Three series are available (1500, 2500, 4000) with capacities of 8 t/h and 55 t/h (wheat based). The “DWU” series of continuous flow dryers are equipped with an efficient stainless steel heat exchanger, which separates the fumes from the drying air, and an air circulation system.

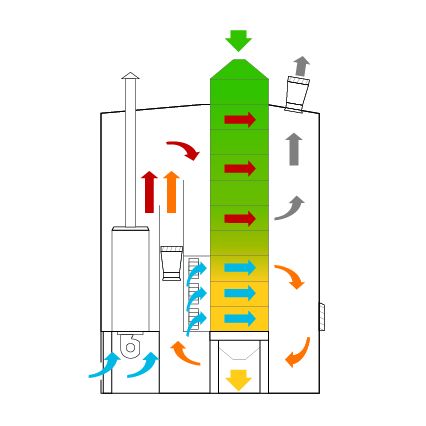

The product enters at the top of the dryer and flows in the direction of the outlet through alternating conical air ducts. During the process, the product is continuously stirred and the hot air from the burner is evenly distributed throughout the product. The required air flow is generated by axial fans located on the roof of the exhaust air duct. The hot air is generated by the burner through a heat exchanger. The air velocity can be adjusted by means of an air valve at the top of the dryer.

The warm air from the lower cooling sections is sucked into the recirculation fans and mixed with the incoming hot air, thus reducing overall energy consumption.

The louvers behind the exhaust fans close when the product enters to prevent dust from entering the exhaust air.

Features

| DWU 15 | DWU 25 | DWU 40 | DWU 60 | ||

|---|---|---|---|---|---|

| Pikkus | (mm) | 6 020 | 8 160 | 8 160 | 9 180 |

| Laius | (mm) | 1 570 | 2 440 | 3 890 | 6 210 |

| Sektsioonide arv | 9 – 14 | 10 – 18 | 12 – 22 | 13 – 22 | |

| Kõrgus | (mm) | 10 885 – 15 335 | 11 775 – 18 895 | 13 555 – 22 455 | 14 445 – 22 455 |

| Tootlikus¹ | (t/h) | 8 – 15 | 15 – 30 | 30 – 64 | 60 – 100 |

| ¹ põhineb nisul | |||||

Tart-Hansu, Mustivere village, 71067 Viljandi municipality, Viljandi county