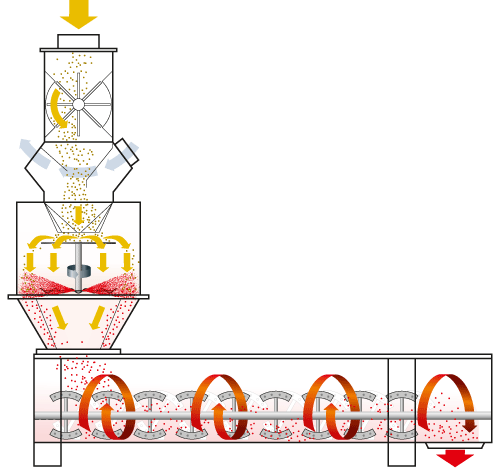

PETKUS CT Continuous Seed Treater — uniform coverage at high throughput

The CT delivers cost-efficient, continuous grain treatment with a single, even layer of coating at up to 25 t/h. It handles a wide range of liquid agents and is suitable for coating and incrustation. Product flows steadily through a generously sized spraying chamber where the agent is finely atomised into a homogeneous mist; gentle mixing paddles then distribute it uniformly while protecting seed quality and ensuring complete emptying. Operation and quality are supervised via a touch panel with integrated sensors.

Key advantages

Single-layer, highly accurate application up to 25 t/h.

Compatible with most liquid treatments; apply up to four formulas simultaneously.

Continuous portioning with speed-controlled rotary feeder.

Aspiration reduces dust in the spraying chamber.

Lined spraying chamber and mixing drum minimise adhesion and ease cleaning.

Gentle paddle mixer with plastic lining for thorough, low-stress mixing and full discharge.

Touchscreen control with sensor monitoring for precise process adjustment.

| CT 05 | CT 10 | CT 25 | ||||

|---|---|---|---|---|---|---|

| Length, L | (mm) | 1 540 | 2 030 | 2 030 | ||

| Width, W | (mm) | 1 000 | 840 | 840 | ||

| Height, H | (mm) | 1 750 | 1 460 | 1 710 | ||

| Productivity¹ | (t/h) | 1 kuni 10 | 2 kuni 10 | 5 kuni 25 | ||

| Amount of cleaning liquid² | (ml) | 150 – 800 | 200 – 800 | 200 – 800 | ||

| Drive capacities | ||||||

| Spray disc | (kW) | 0,75 | 0,75 | 0,75 | ||

| Last mixing unit | (kW) | 0,55 | 1,5 | 1,5 | ||

| Liquid pump | (kW) | 0,18 / 0,37 / 0,55 | 0,18 / 0,37 / 0,55 | 0,18 / 0,25 / 0,55 | ||

| Sector feeder | (kW) | 0,37 | 0,37 | 0,37 | ||

| ¹ based on wheat seeds | ||||||

| ² ml per 100 kg of seeds | ||||||