PETKUS K-grain graders are optionally available with or without drift cylinders. The K-series stands for robust and reliable grading machines that are the best choice for small-scale industrial or commercial cleaning of cereals, oilseeds, pulses, hay and vegetable seeds. High cleaning performance is achieved by combining several cleaning processes (screening system, aspiration system and rotary cylinders).

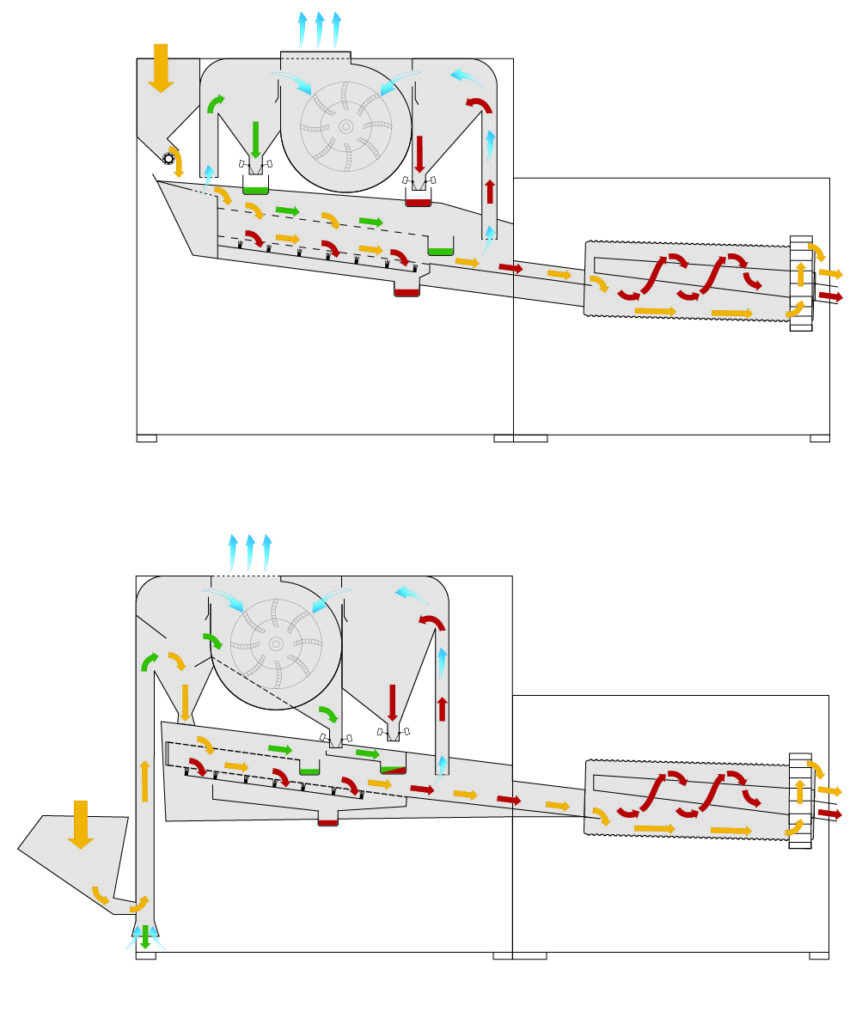

From the inlet point, the product passes through the first aspiration channel, where light and dust particles are separated. The seed then passes to the screening system. The upper sieve separates large and coarse impurities and its sieve opening is cleaned with small hammer blades. Small impurities are separated through the lower sieve and the lower sieve is cleaned from below with brushes. The sieved product passes through the last aspiration channel where the air stream separates the smaller and lighter impurities. The cleaned seeds pass on to the rotary cylinder where short impurities such as half grains and round weed seeds are separated. The cleaned seed then passes from the dripper cylinders to the bags.

| K 531 + trior block | K 541 + trior block | K 12 | K 06 | ||

|---|---|---|---|---|---|

| Length | (mm) | 4 845 | 4 717 | 3 037 | 2 914 |

| Width | (mm) | 1 972 | 1 337 | 1 972 | 1 337 |

| Height | (mm) | 2 248 | 2 100 | 2 248 | 2 100 |

| Weight | (kg) | ca. 1 900 | ca. 1 150 | ca. 1 400 | ca. 920 |

| Productivity | (t/h) | ||||

| Intensive cleaning | 3,5 | 1,75 | 4,0 | 1,75 | |

| Seed cleaning ² | 2,5 | 1,25 | 2,5 | 1,2 | |

| ² based on wheat, moisture content ≤ 15%, impurities ≤ 2% | |||||