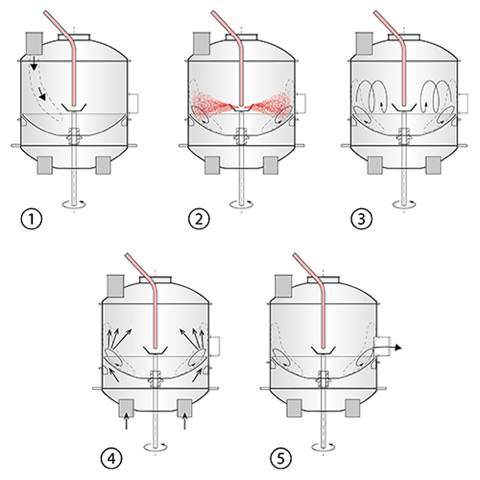

The PETKUS/ROEBER MultiCoater CM series is an innovative machine for processing seeds with different liquids and granulating with different powders. The PETKUS CM machine uses air cushion technology for seed processing and granulation, which allows gentle processing and subsequent drying of the seeds and, in addition to reduced friction, no dust is released from the seed surface. All treatments, including liquids, dyes, polymers or other granulation and coating agents, may be used sequentially and/or at different times and intensities. One seed lot may be simultaneously processed and dried in the apparatus. Coated or granulated seeds do not need to be dried in subsequent stages as the whole process takes place in one step.

MultiCoater works on the rotor-stator principle. The seed is loaded into the mixer in portions. The dosing of liquids and additives is done by means of inductive flow meters. The seed is fed by means of a precise electropneumatic batch scale and gravimetric dosing. The liquid and seed quantities are continuously measured and thus the actual and target values are compared and automatically adjusted throughout the process. The perforated spray disc produces an extremely fine dispersion of liquids under a wide spray angle. The rotor and stator are made of smooth polished stainless steel, so there is no fear of residues of various liquids sticking to the surfaces of the unit. Plastic guiding elements, resembling the shape of an aircraft wing, optimally and aerodynamically pull the seeds towards the centre of the device, ensuring excellent mixing.

The innovation of MultiCoater is based on sophisticated air management. Air passes through the nozzles and there is an adjustable gap between the stator and the rotor. This creates an air cushion between the stator wall and the seeds, dramatically reducing friction. At the end of the coating process, the air flow rate can be increased to further dry the seed. Coated seeds do not need to be dried in the second stage of the process.

| CM 25 | CM 100 | CM 300 | ||

|---|---|---|---|---|

| Productivity | (t/h) | Up to 1,8 | Up to 8,5 | Up to 25 |

| Length | (mm) | 1 582 | 2 050 | 3 160 |

| Width | (mm) | 1 184 | 1 550 | 3 130 |

| Height | (mm) | 1 658 | 2 020 | 2 500 |

| Air volume | (m3/h) | Up to 3500 | Up to 8000 | Up to 15 000 |

| Container volume (wheat) | (kg) | 25 | 100 | 300 |

Tart-Hansu, Mustivere village, 71067, Viljandi parish, Viljandi county, Estonia