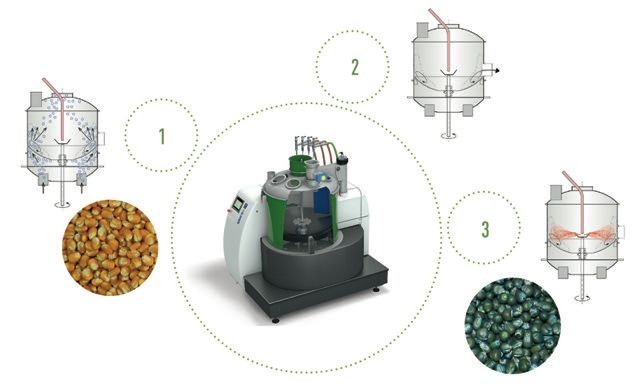

The MultiCoater CM HySeed unit sanitizes and disinfects seeds with active steam, providing an efficient, gentle and above all fast and targeted heat transfer that can penetrate the seed. Eliminates a wide spectrum of pathogens, including fungi and bacteria.

HySeed bio uses an advanced seed batch mode for hygiene, so that individual treatment recipes can be applied independently but in the same unit.

In addition to the processing module (the mixer), the technology is also based on an automatic evaporator capable of delivering high temperature and high humidity steam in a short time. An additional air mix ensures gentle seed treatment and precise control of the steam temperature. The heat kills pathogens, while the humidity helps to intensively and quickly transfer heat into the grain. This ensures effective control of seed-borne infection even in the deepest layers of the seed.

Steam-treated seeds can be dried in a single process step. In order to avoid loss of performance, the HySeed bio unit itself dries the seed for only about 1 minute and the final drying can take place in a separate belt or flat-air dryer. The drying process on the seeds takes about 5 minutes until one batch is completely dry. The steam treatment on the seeds takes only 1,5 minutes.

As a complement to hygiene/disinfection, liquids and powders can still be used for treatment in the HySeed bio. This provides complete seed treatment against soil-borne pathogens.

The whole HySeed bio-processing process is fully automated and follows a developed recipe (including different temperature specifications). The records and processing parameters used throughout the seed treatment process can be retrospectively monitored by the operator.

| Max. productivity | CM25 HySeed bio | CM100 HySeed bio | CM300 HySeed bio | |

|---|---|---|---|---|

| Wheat | (t/h) | Up to 0.275 | Up to 1.2 | Up to 4.1 |